Everglide aluminium profile gains momentum as 12 fabricators switch

Posted on 14/05/2024

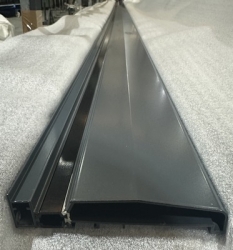

Leading manufacturer AT Precision has announced a significant surge in demand for its Everglide aluminium profile for bi-fold doors.

In the past year since its launch, an impressive 12 fabricators have switched to Everglide profile, having previously sourced their systems from alternative suppliers.

Everglide profile is manufactured in-house at AT Precision’s state-of-the-art facility in Durham. This meticulous in-house production process allows the company to deliver exceptional quality at competitive prices, a key factor in attracting new customers.

“We’re delighted with the positive response we’ve seen to Everglide profile,” comments Sales Director Michael Hewitt. “Fabricators are recognising the significant benefits it offers, not only in terms of cost-effectiveness but also in quality and performance.”

Everglide profile boasts impressive technical specifications, including a U-value of 1.5W/m²K and full Document L compliance, ensuring exceptional thermal performance.

With maximum sash dimensions of up to 1,200mm wide and 2,500mm high, the profile offers superior design flexibility, catering to a wide range of project requirements.

“Everglide profile caters to the growing trend for larger bi-fold door applications,” Michael explains. “The ability to support sashes up to 100kg in weight makes it ideal for projects demanding expansive glazed areas.”

Fabricators choosing the Everglide profile benefit from a true one-stop shop for all their bi-fold door needs.

AT Precision offers a comprehensive portfolio of products, including the Everglide range of bi-folding door rollers, guides, and hinges, the Everseal range of gaskets, and a wide range of security hardware, eliminating the need for multiple suppliers and streamlining the procurement process to save valuable time and resources.

For more information on Everglide aluminium profile and AT Precision’s complete range of bi-fold door components, visit www.atprecision.co.uk.